The recent grand opening of Denver’s Trust Press marked a huge milestone in our industry. This event culminated the fulfillment of a vision that started several years ago, featuring the newly acquired Denver Press. The National Trust now owns and operates over 60 newspapers in Maine, Colorado, and Georgia, providing essential community news to nearly 40 counties and approximately five million people. This event was attended by customers and donors from the Gates Family Foundation, Bohemian Foundation, The Colorado Trust, Colorado Media Project, Boettcher Foundation, and other contributors. The opening was not just a celebration but a step forward in reinforcing the vitality of local news.

Kevin Smalley, Director of The Trust Press, led attendees through an instructional tour starting in the plate room, moving to the plate bender, and culminating in a live demonstration of plates being loaded and a Pressrun. Amalie Nash, Head of Transformation at the National Trust for Local News, engaged with guests, saying, “It was such a fun and inspiring evening on Thursday as the National Trust for Local News officially unveiled The Trust Press to our supporters, partners, and friends in this new endeavor!” Detailing ongoing efforts to secure funding and outlining future plans to address “news deserts,” her discussions spoke to the dedication of the National Trust to protect and uphold integrity in community news. She highlighted the financial strategies intended to sustain the Trust Press long-term, emphasizing the importance of continued donor support to achieve these goals.

“A highlight of the event was printing a special section on the press, about the press. Deep gratitude to everyone who has been part of this journey,” stated Nash.

Dave Gilmore, Vice President of Sales at imPRESSions Worldwide, spoke a few words at the Open House, sharing insight into the collaborative effort between iW and Trust Press that led to the installation of the four-tower DGM 430 Press, specially designed for the smaller print runs that local publishers require. The Press has the capacity to print dozens of other local and ethnic newspapers, in addition to Colorado Community Media newspapers. Trust Press is not only creating jobs for the community but is also estimated to save local publishers at least $500,000 in 2025 compared to existing printing options, according to the National Trust, demonstrating its potential as a cost-effective alternative for printed publications. The grand opening also served as a showcase for future projects that will drive Trust Press forward. imPRESSions Worldwide’s role in equipping the facility highlights our dedication to delivering tailored solutions and supporting the ecosystem of local news. We at imPRESSions Worldwide take our hats off to the Trust Press, The National Trust for Local News, and all the folks who support and uphold a commitment to community news—keeping “Ink on Paper,” offering an oasis for communities across Colorado and beyond.

The event provided an 8- page Commemorative Issue to celebrate the Trust Press Grand Opening—a keepsake for attendees to remember the significant strides made toward sustaining local journalism.

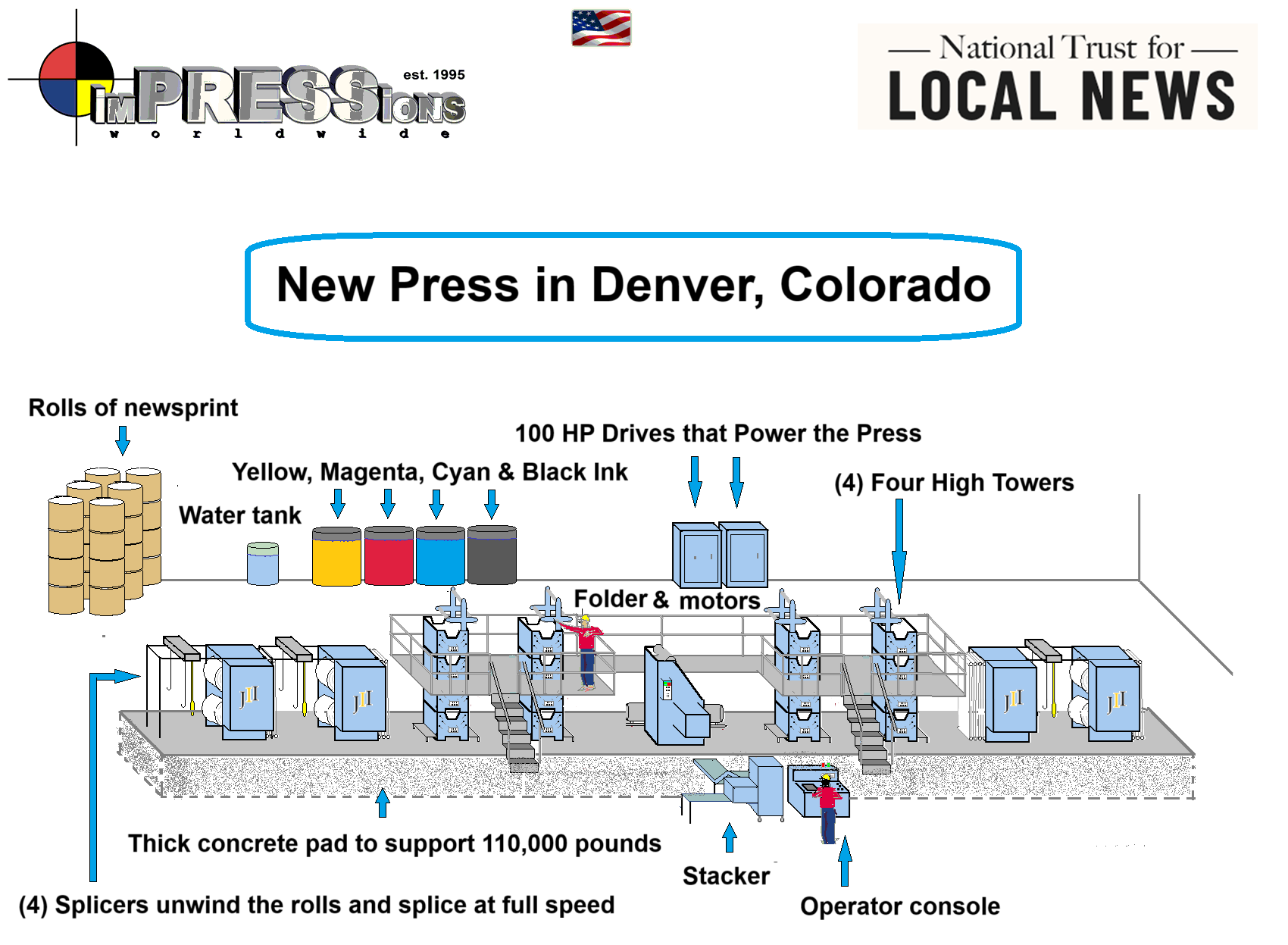

Machine learning: What it took to set up the Press: The centerpiece of the Trust Press is a four-tower DGM 430 Press ImPRESSions is honored to have supplied, delivered, and installed the new Trust Press. I believe community newspapers will never abandon print. The critical role that the National Trust for Local News has undertaken cannot be underestimated, especially at a time when large media companies are moving away from print, creating “print deserts.” They are closing their large printing Press plants because the big city daily newspapers are racing to the digital finish line. Community newspapers that deliver news that is not as time-sensitive rely on print and will continue to do so into the future. Let me introduce you to the machine that is now the centerpiece of the Trust Press. Some interesting facts about this offset web printing Press:

- It’s 90 feet by 10 feet long and about 24 feet wide.

- The tallest point is just under 16 feet.

- It prints 32 tabloid pages at 25,000 copies per hour.

- It has four 4-highs in the Press, and each can print the same image in cyan, magenta, yellow and black, creating fullcolor photos and graphics.

- It is powered by multiple DC (direct current) motors, which provide the low-end torque to get the big beast out of the hole on a cold Colorado morning.

- It uses 3-phase power at 480 volts to spin the motors and turn the main driveline at speeds over 1,000 rotations per minute. Operating a machine like this takes both finesse and, at times, brute force.

- This behemoth weighs 110,000 pounds and is constructed primarily from cast iron and steel parts.

- There are miles of wire on a press like this, and more than 1,000 connections had to be made during the installation.

- The splicers unwind 1,000-pound rolls of paper and feed it to the Press. Once the roll is unwound and threaded through the Press units and folder, it is referred to as a “web.” They can splice an expiring roll into a new roll at full speed, so four web production is non-stop once a job is underway.

During the installation process, every component—from units to folders and splicers – was carefully leveled and then aligned with each other to a tolerance that is less than a human hair. The individual pieces were anchored to the floor and secured with additional above-ground concrete. The complete installation can then be referred to as a single-wide, single-around offset web printing Press. When the Press is installed perfectly, each “web” will track on the centerline of the press, and there will be no wrinkles.

“This Press isn’t just a machine: it’s a guardian of the community, set to produce beautiful newspapers that champion and protect the community for decades to come.” Tom Loesch – imPRESSions Worldwide